There are a lot of variables that go into creating a quote for your custom project. In this post we are breaking down some of the most important considerations for your next project to help you understand all the important details we’ll need in order to deliver the best possible product to you.

We take great pride in our ability to deliver custom solutions, quickly, and for a great investment. The more alignment we gain with you, the more satisfied you’ll be!

Project lead time is one of the biggest questions we are asked, especially in today’s environment. In an effort to deliver your project as soon as possible, we framed up five key questions that you can answer for us in order to get you an accurate quote sooner rather than later.

Before we dive in, we want to ask which category you fall into:

- Yes, I have experience with t-slot products.

- No, I do not have experience with t-slot products.

If you do have experience with t-slot products, you may skip down to the section below, Questions to answer for your fast & accurate quote.

If you do not, it’s best not to overwhelm yourself with all of the various options regarding connection types, profiles, hardware, etc.

The minutia can be overwhelming, so let’s keep it simple when submitting an RFQ for the first time. Feel free to scan the information below but do not worry if you’re unsure of what the question is asking.

Please just indicate in the form fill, email, or while on the phone with a Faztek representative that this is your first foray into t-slot and you’re going to need some education along the way to delivering an RFQ to you. We are happy to coach you through the process.

Questions to answer for your fast & accurate quote

1. Product selection – what product line of ours are you here for?

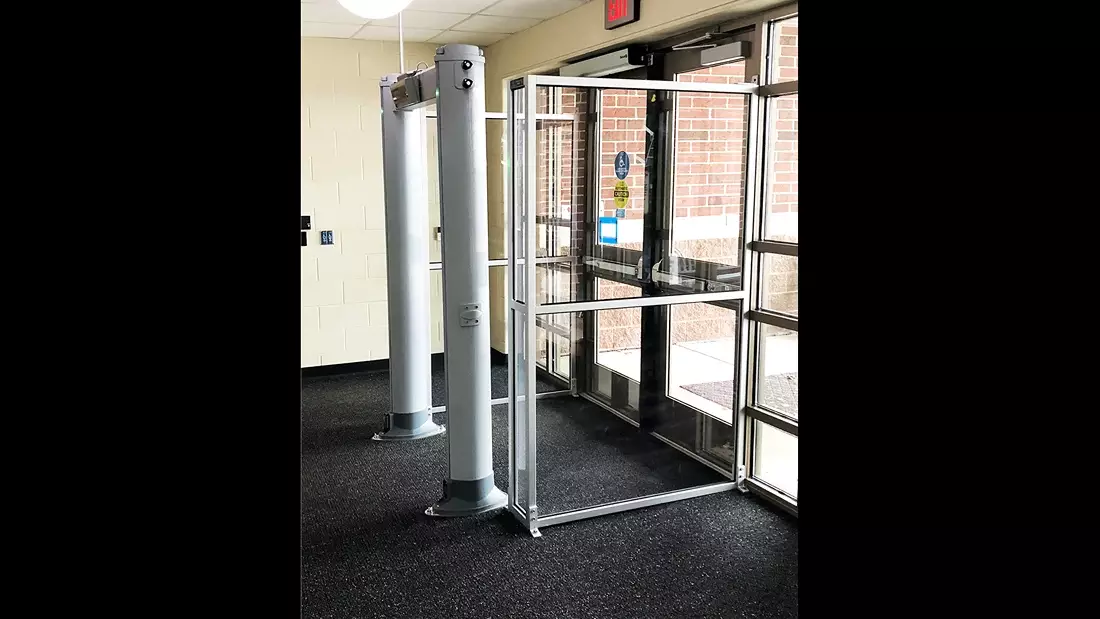

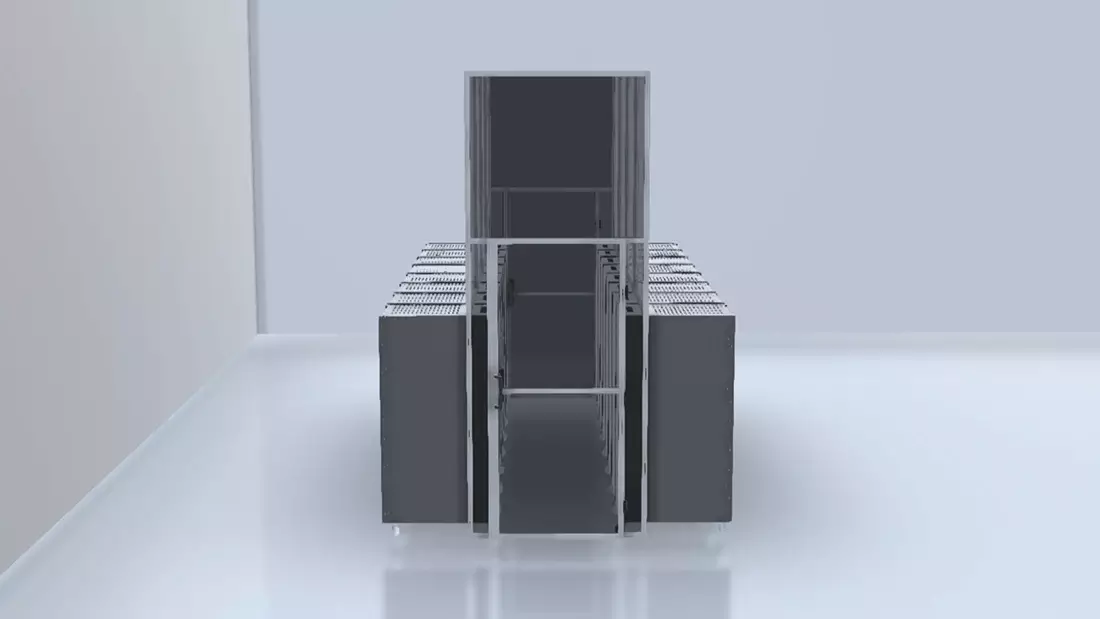

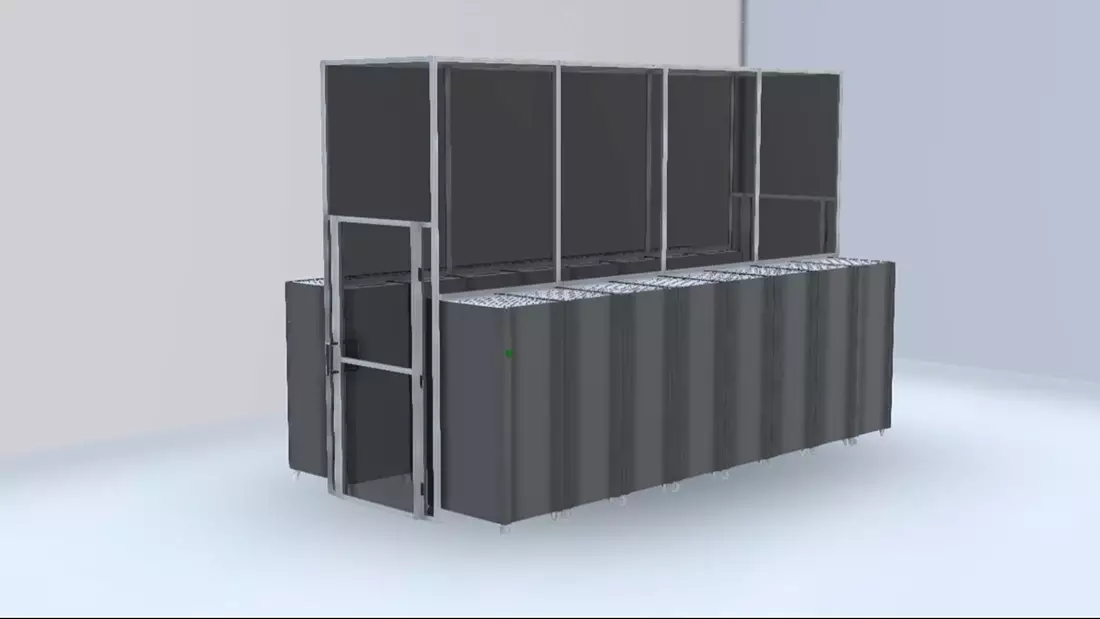

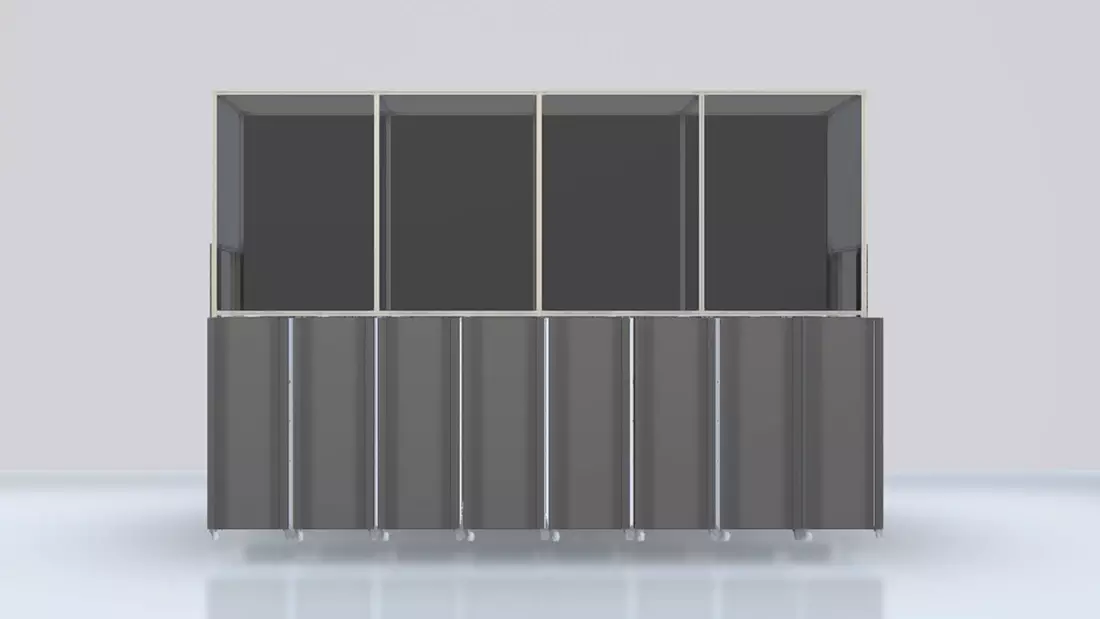

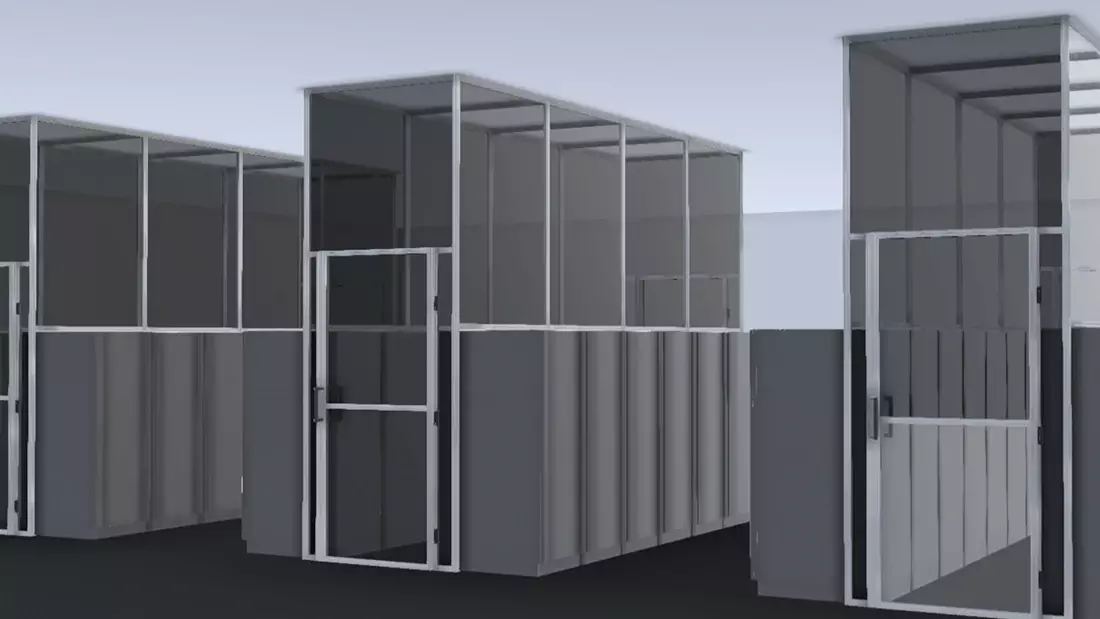

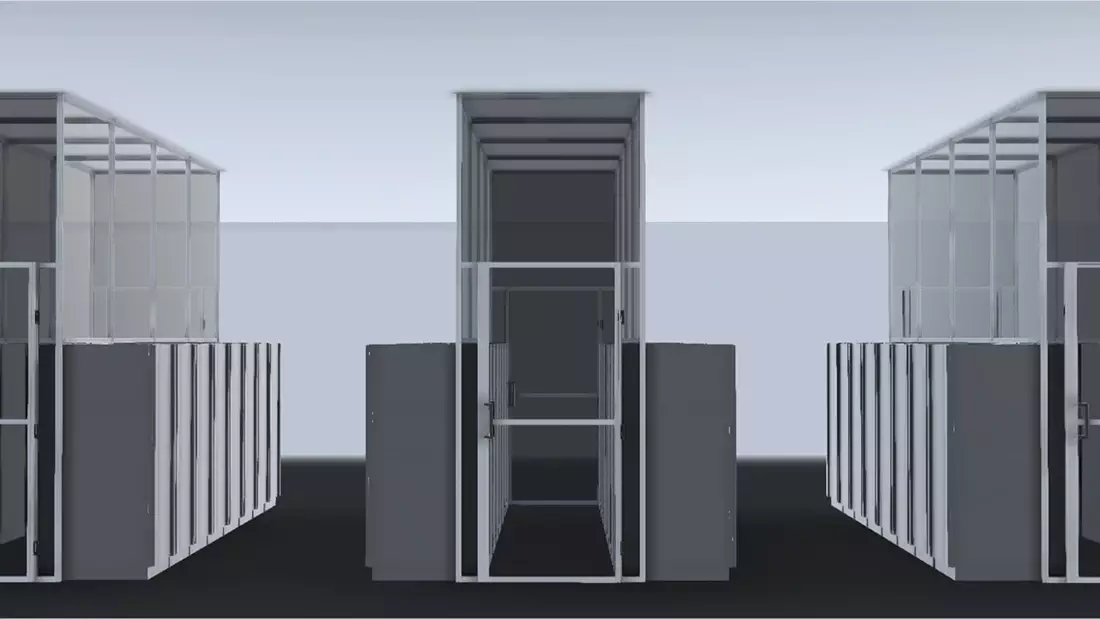

a. Data centers walls, panels, and doors

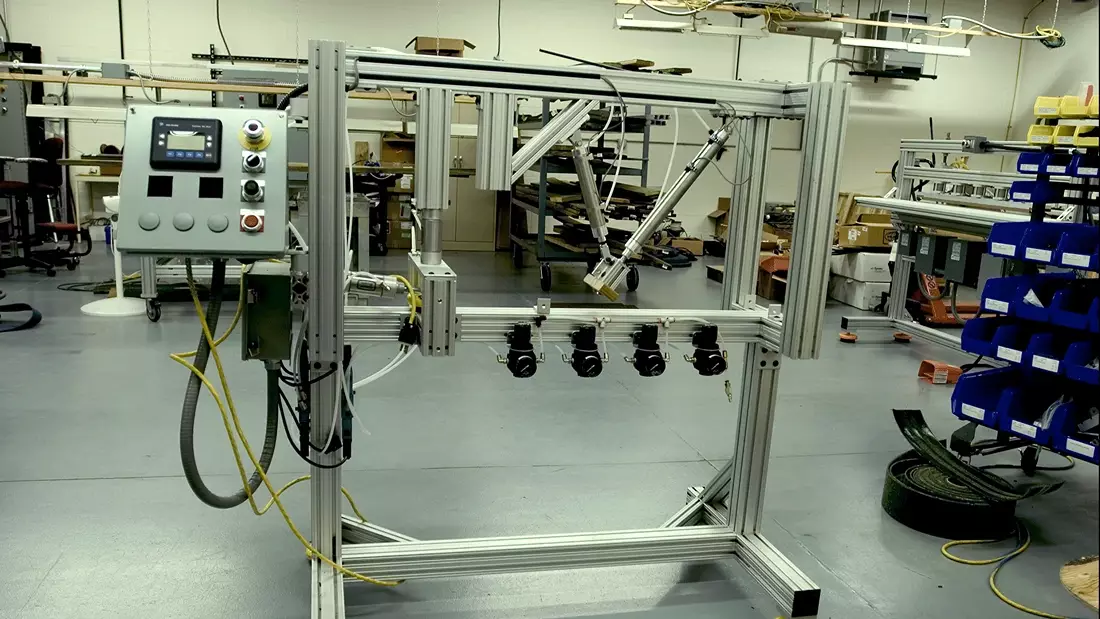

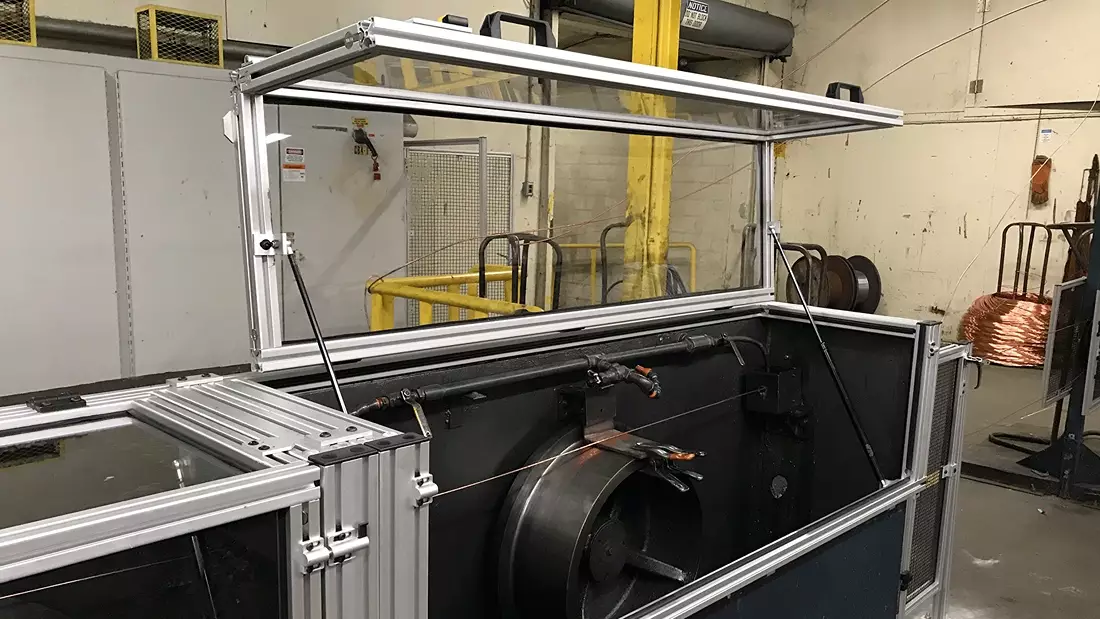

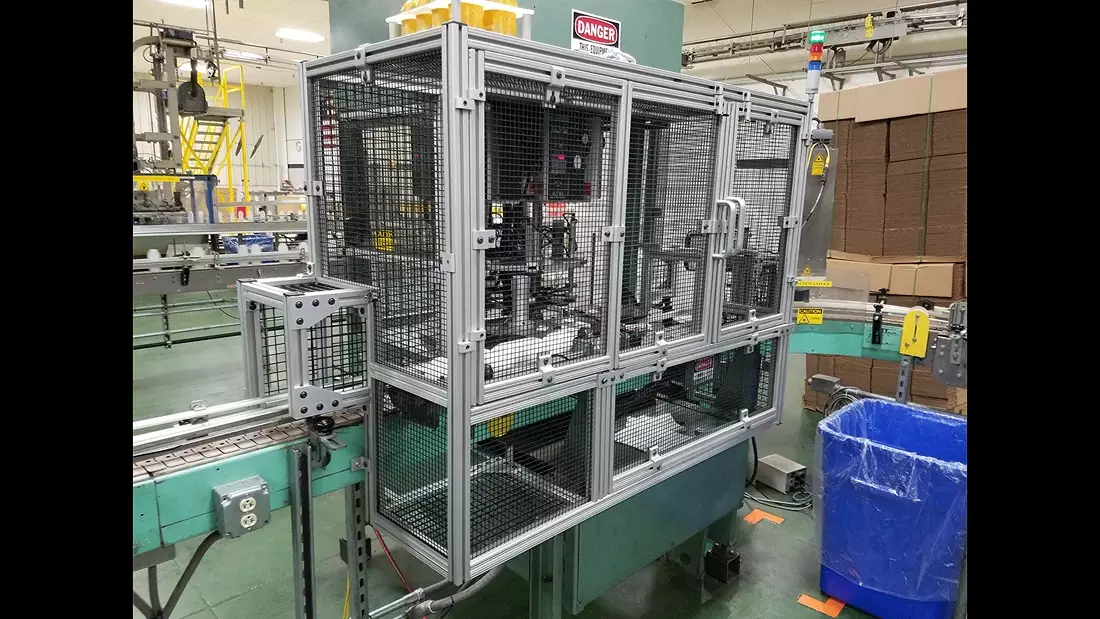

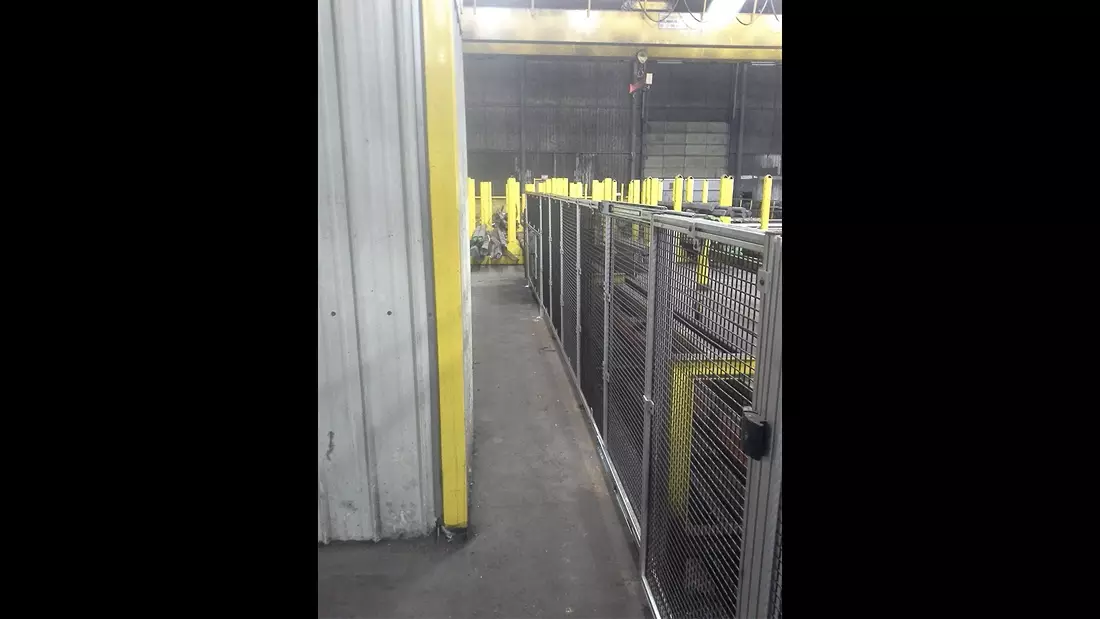

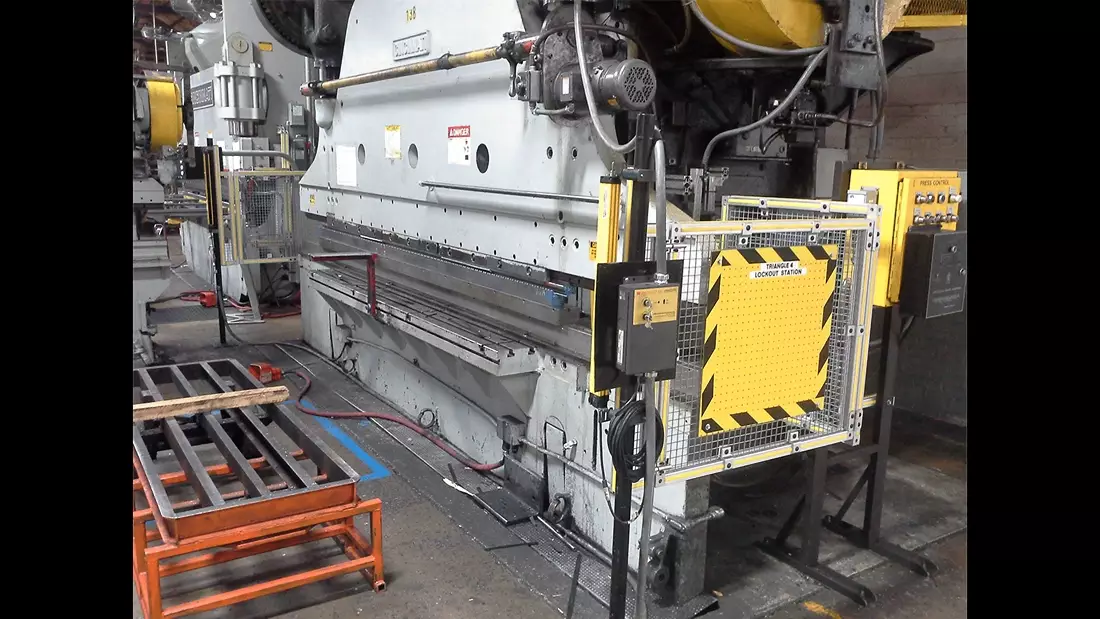

b. Machine guarding

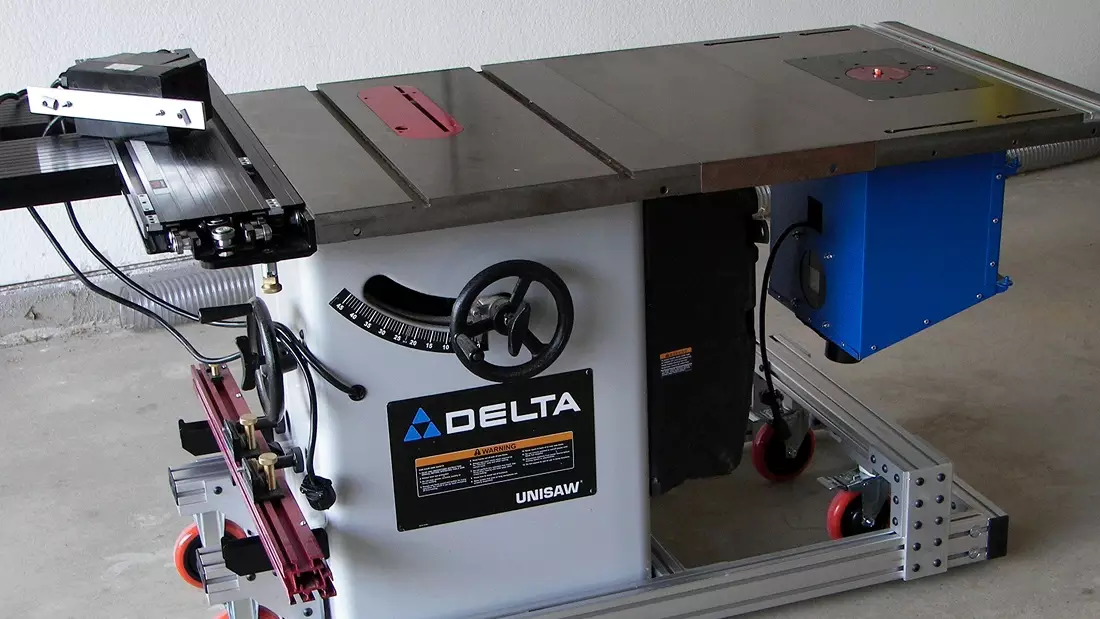

c. DIY projects

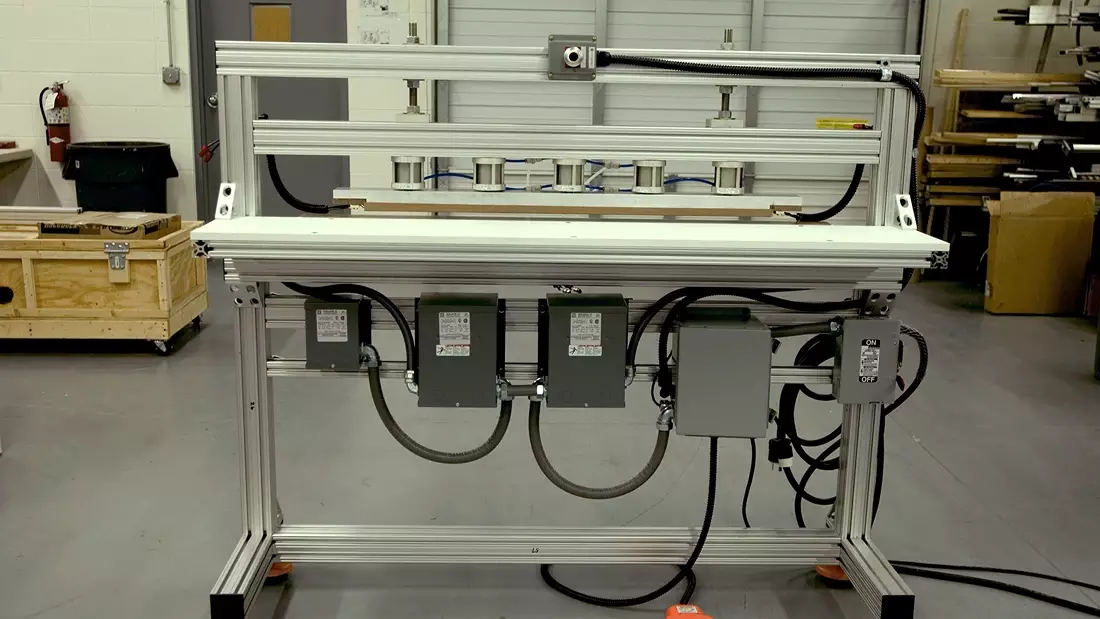

d. General industrial solutions such as carts, tables, and machine stands

e. Work stations

Please share a picture if you have one! A drawing, whether it’s a CAD drawing or a simple sketch, is very helpful.

2. Project context details:

This may seem like an odd question but here’s an example of a request we often receive and the questions we have to determine the final specs for the customer:

Customer will say they “want a door.” In order to deliver exactly what they need, we would need to know:

- Where this door is going

- What type of door is it (such as a human sized door or machine sized, so as to accommodate a forklift, as an example.)

- What size does it need to be?

Dimensions are probably the most critical. Length, width and height, along with any critical dimensions relevant to your project depending on the design’s complexity. - What will your project solution be used for?

- What sort of work environment will your project be in / where will it go?

- About how big should your project solution be?

- Do you have specific material requirements or preferences?

- Will this be mounted or secured to something else?

3. Materials and strength profiles requirements and preferences:

We create a variety of different projects for a lot of different use-cases. Regardless of what you’re requesting a quote for, strength profiles are important to consider to ensure your project isn’t over or under engineered.

- In regards to weight load, this will be pertinent to the designer who will determine what extrusion profile will best serve the project’s needs. For instance, if you intend to build a workbench, we need to know if anything over 100 pounds will be applied to the table surface, or will your workbench hold over 1000 pounds? This detail alone will allow us to determine the profile and general structure of the design. Over engineer it and you’ll pay more than you need to. Under engineer it and the design won’t support your expectations!

- Paneling is relevant for a few reasons. Is the end user sourcing it themselves or will Faztek need to provide it? Faztek typically stocks 1/4″ black ABS and 1/4″ clear poly, along with thinner material for smaller extrusion profiles. Again, don’t overthink it. Decide if you want paneling and where it should be located on the design.

- We currently offer 4 different profiles series consisting of different weights and profile designs; 15, 10, 40, and Faz-Tube. Each series offering different weight deflections, price points, and expandability. 15 series being the most common and coming in 1.5” increments, 10 series is 1” increments, 40 series is 40 mm increments and Faz-Tube strictly in 1”x1” hollow profile, and assembled using a boltless fastening system.

4. Are you going to assemble the project yourself or do you want us to do it for you?

You have two options when it comes to the assembly of your project. If you choose to assemble it yourself, know that all of our projects are customized so we do not provide a specific set of directions for assembling your project. If this is your first time dealing with t-slot, let’s discuss the feasibility of doing this yourself.

We have a decision guide to help you determine if you’re equipped to assemble your project yourself of not: Faztek As Your Assembly Partner

5. How do you want your project delivered to you? Shipping details:

Another important point, especially for the DIY crowd, is shipping. Size and weight will determine whether the project can get to you using standard ground shipping, or if it will require less-than-truckload (LTL) truck freight coordination. A thought to keep in mind, if you are determined to keep shipping at standard ground only; keep the dimensions below 96″.

Is Faztek the right partner for your next project?

By providing us with some of the answers to the questions above we will be able to provide you with a fast, accurate quote to help you determine if we’re the right partner for your next project.

If you’re interested in learning more about the Faztek advantage, read this article: Is Faztek the right partner for your project?

CALL TODAY

CALL TODAY