Aluminum Extrusion Technical Data

Drop-Lock Feature

- Properly tighten fasteners to ensure a vibration-proof frame!

- A 1°-2.2° drop-lock feature is a taper from the aluminum extrusion t-slot face to the t-slot center.

- All Faztek’s aluminum extrusion t-slots are extruded with this feature (except ’40QE’)

- A drop-lock allows the aluminum extrusion t-slot to be drawn up to the mating mounting surface, virtually acting as a lock washer.

Extrusion Properties

- Twist: (measured in degrees)

- 0EX1010/10QE1010 = 1 x measured length (ft)

- All other aluminum extrusion t-slot larger than 10EX1010/10QE1010 = 0.500 measured length (ft)

- Straightness: 0.010″ x L’ (measured length)

- Flatness: 0.004″ x W” (width of part)

Mechanical Data

- Aluminum begins to soften at 400 degrees – Once aluminum softens, it stays in that state.

- Modulus of Elasticity: 10,000,000 lbs / sq in.

- Melting Point: Between 1140° to 1210°

- Yield Strength: The point at which material stretches– T6 = 25,000 psi minimum.

- Elongation: The difference between tensile and yield strength (how material stretches).

- Elongation A10 (material up to .124 thick = 8%) Elongation A5 (material greater than .124 thick = 10%)

- Rockwell Hardness (Webster): E scale of E50

- Tensile Strength: The point at which material fractures – T6 30,000 psi minimum.

Alloy

An aluminum extrusion alloy is a predetermined mixture of one or more elements together with aluminum to be heated and hydraulically pressed through an extrusion die. Some common elements alloyed with aluminum include Copper, Magnesium, Manganese, Chromium, Silicon, Iron, Nickel, and Zinc. Faztek T-Slotted Aluminum Extrusions are extruded using a 6063 alloy. The major alloying elements for this alloy include Mg .45% -9% and Si .20% -6%.

Anodizing

Anodizing is an electrochemical process that thickens and toughens the naturally occurring protective oxide. The resulting finish makes a corrosion-resistant aluminum extrusion. Faztek t-slot extrusions have an etched anodized finish that is 0.15 – 0.25 mil.

General Characteristics

- Not Magnetic

- On a weight basis, aluminum is the most efficient thermal conductor

- Won’t Rust

- Won’t Burn

- 1/3 Weight of Steel on a weight basis, aluminum is the most efficient thermal conductor

Deflection Calculations

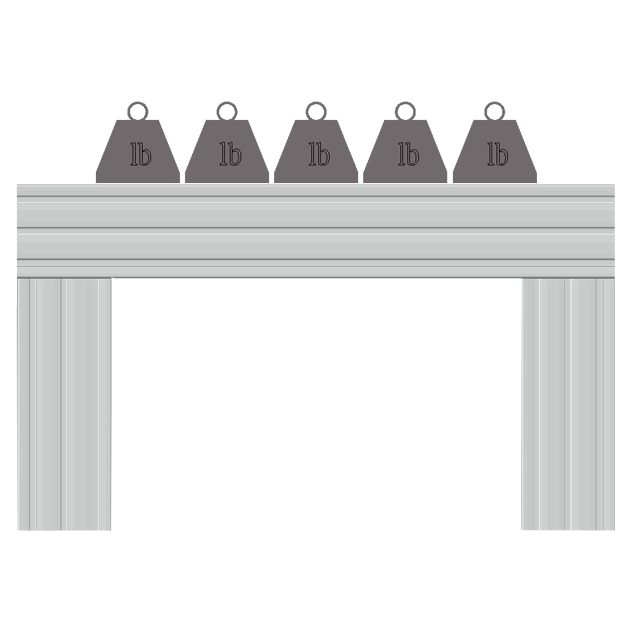

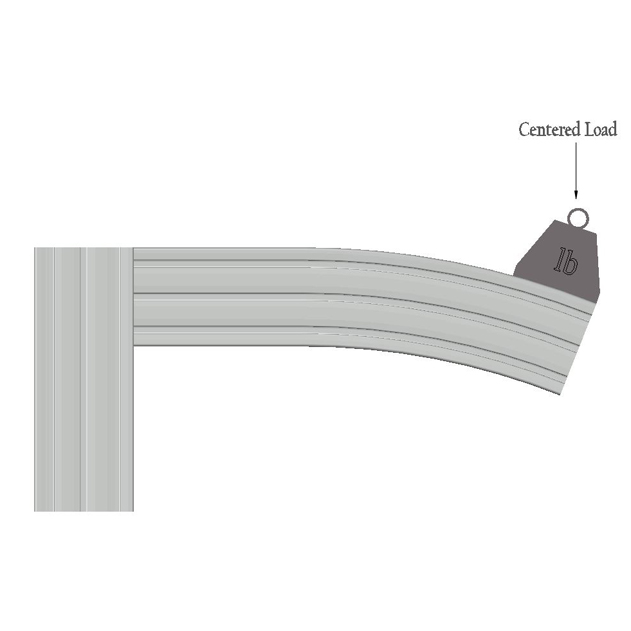

Support Loads

Determining the difference between the industry standard of 6063-T6 and other companies using 6105-T5

Example: Using 1.5” x 1.5” Standard T-Slotted Extrusion at a length of 36” with an applied force as shown below of 50 lbs, the deflection of the T-Slotted Extrusion will be approximately .018195 using 6063-T6 material and .018743 using 6105-T5. You will find less deflection in this application using 6063-T6.

Deflection Calculation for 6063-T6

50 * 36 * 36 * 36

40 * 10,000,000 * .2671

2332800

128208000

.018195″

Deflection Calculation for 6105-T5

50 * 36 * 36 * 36

40 * 10,000,000 * .2671

2332800

128208000

.018195″

As you can see, the deflection is negligible. With technical factors being almost equal for T-Slotted Extrusions, the critical decision should be based on the service and support offered by the factory and its supporting Distribution!

Pressurizing T-Slot Cavity

Faztek’s aluminum extrusion t-slot cavity can be pressurized up to 150psi. This is extremely useful for numerous applications such as workstations and workbenches for liquid flow (water, coolant, gas, etc.) and air tools

The table below lists specific values for each aluminum extrusion t-slot.

|

Profile Model

|

Value |

|

10EX1020

|

0.357 sq / in |

|

10QE1020

|

0.357 sq / in |

|

10EX2020

|

1.587 sq / in |

|

10QE2020

|

1.587 sq / in |

|

15EX1530

|

0.814 sq / in |

|

15QE1530

|

0.814 sq / in |

|

15EX3030

|

3.626 sq / in |

|

15QE3030

|

3.626 sq / in |

Example: What is the volume for a 15EX3030 at 32.00″ long?

Volume (cu in) = Constant value (sq in) x Length of the Extrusion Volume (cu in) =

3.626 x 32.00″ Volume (cu in) =

116.032 cu in

Torque Ratings

|

Fastener Description

|

Tested Extrusion

|

Torque (min) ft-lbs |

Torque (max) ft-lbs

|

|

15FAC3880 – Anchor Fastener

|

15EX1515L

|

17

|

22

|

|

15FAC3865 – End Fastener

|

15EX1515L

|

17

|

22

|

|

15FAC3890 – “T” Anchor Fastener

|

15EX1515L

|

17

|

22

|

|

10FAC3750 – Anchor Fastener

|

10EX1010

|

17

|

22

|

|

10FAC3755 – End Fastener

|

10EX1010

|

17

|

22

|

|

5/16-18 FBHSCS/Economy T-nut

|

15EX1515L

|

15

|

20

|

|

1/4-20 FBHSCS/Economy T-nut

|

10EX1010

|

13

|

18

|

|

15FAC3880 – Anchor Fastener

|

15QE1515L

|

17

|

22

|

|

15FAC3865 – End Fastener

|

15QE1515L

|

17

|

22

|

|

15FAC3890 – “T” Anchor Fastener

|

15QE1515L

|

17

|

22

|

|

10FAC3750 – Anchor Fastener

|

10QE1010

|

17

|

22

|

|

10FAC3755 – End Fastener

|

10QE1010

|

17

|

22

|

|

5/16-18 FBHSCS/Economy T-nut

|

15QE1515L

|

15

|

20

|

|

1/4-20 FBHSCS/Economy T-nut

|

10QE1010

|

13

|

18

|

CALL TODAY

CALL TODAY