In the bustling world of manufacturing, where machinery never sleeps and productivity is paramount, one principle reigns supreme: safety. It’s more than a priority; it’s the core of every operation. Every person who steps onto the factory floor knows the importance of proper machine guarding. Such commitment means one size does not fit all as it relates to guarding. That’s where Faztek makes its mark, offering customized guarding solutions meticulously tailored to meet your equipment’s needs and operational flow.

This blog explains the precision of Faztek’s custom machine guarding. Here, every guard and barrier is not just a safety feature; they’re carefully crafted pieces of a larger puzzle designed to integrate seamlessly with your unique manufacturing environment. Join us as we explore how Faztek’s approach to customized guarding solutions transforms standard safety protocols into a robust, personalized safety framework, ensuring your facility operates smoothly and safely.

Custom Guard Design and Planning

Creating a safe work environment is a deliberate process that begins with a smart, well-thought-out guard design. At Faztek, we excel in translating your safety requirements into practical, efficient guarding solutions. Our approach is hands-on and collaborative, offering free consultations and detailed planning assistance to make sure your safety measures are compliant and perfectly tailored.

Understanding Your Equipment and Guarding Requirements

Our process starts with a deep dive into the types of machinery and moving parts in your facility. Whether it’s high-speed rotating equipment, press machines with dangerous pinch points, or automated assembly lines, each piece has certain guarding needs. We meticulously assess the operational risks and design guards that provide optimal protection without hindering your operational efficiency.

Tailored Guarding Solutions

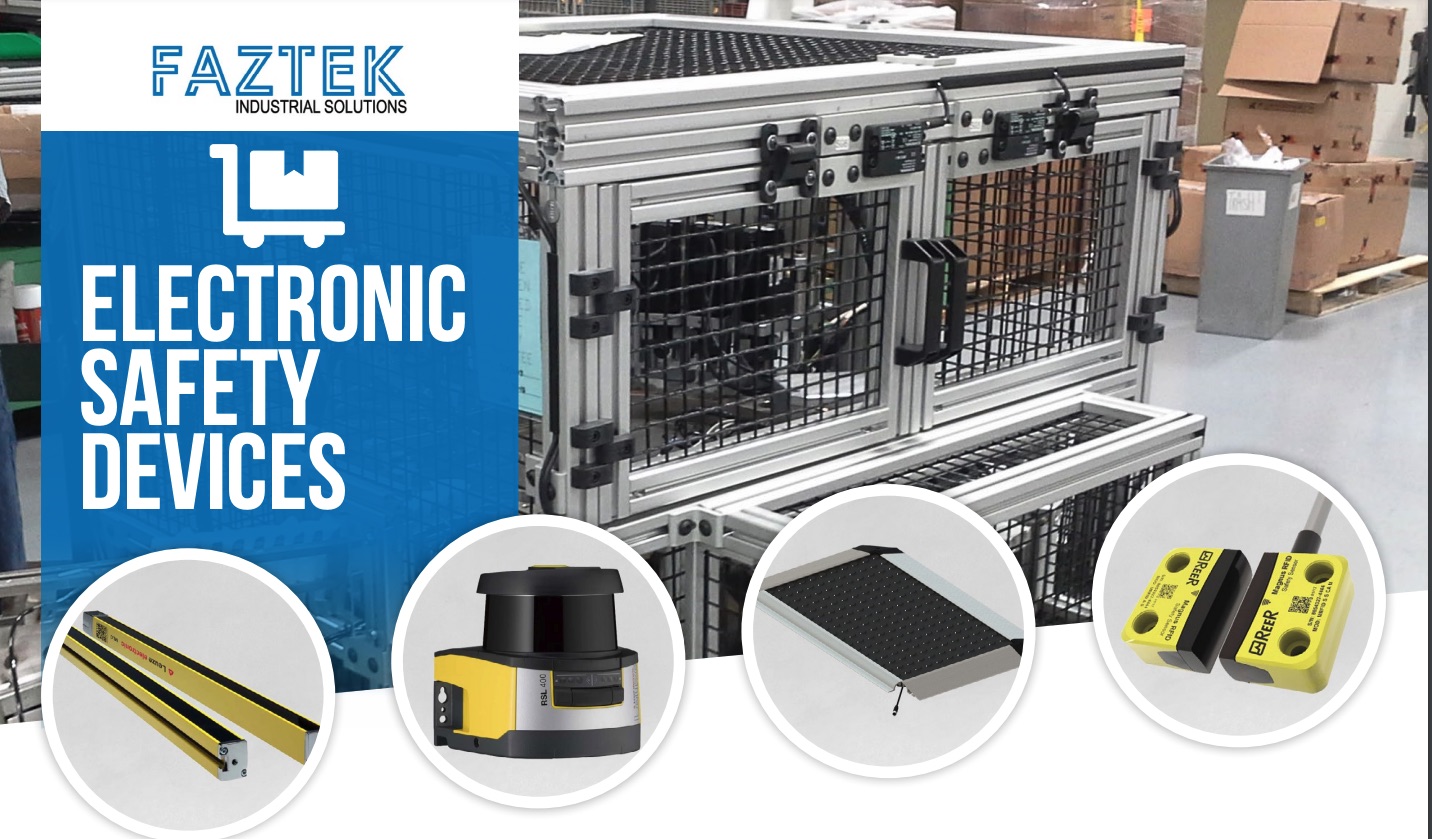

Below is our range of guarding solutions:

- Machine Enclosures: Such enclosures encapsulate specific machines or operation points as the first line of defense, ensuring operator safety without compromising machine accessibility.

- Hybrid Guards: This flexible solution combines two or more safety products, like mesh screens with electronic sensors, to address your operation’s complex or varied safety needs.

- Perimeter Guards: These barriers are essential for delineating work zones, restricting unauthorized access, and maintaining a clean, organized, and safe work environment.

Material Selection for Durability and Function

Choosing the right material is crucial for the effectiveness and longevity of your guards. We offer a selection of materials, such as robust steel for high-impact protection, lightweight aluminum for ease of handling and corrosion resistance, and transparent Plexiglas for visibility and light penetration. Faztek selects the material based on your specific environmental conditions, usage requirements, and safety standards.

Integration with Safety Interlocks and Control Systems

To enhance the functionality of our guards, we integrate them with advanced safety interlocks and control systems. From light curtains that create invisible safety barriers to interlock switches that ensure safe access points, our electronic safety devices can operate independently or seamlessly with your guarding solutions. This automation integration turns a passive guard into an active safety system, providing additional protection and peace of mind.

Custom Accessories

Recognizing the distinct nature of every industrial setup, Faztek brings an array of custom accessories designed to complement and enhance your machine guarding systems. It’s not just about the primary guarding solutions; it’s also about the minor details that perfect the functionality and adaptability of your safety measures.

We curate a range of custom accessories to address each aspect of your guarding solution.

- Locks and Latches: Security is of prime importance, and we design our locks and latches to keep your guarding systems secure while providing easy access for authorized personnel. Whether preventing accidental openings or ensuring the guards remain in place during operations, these components are vital for maintaining the integrity of your safety barriers.

- Leveling Feet: Uneven floors? No problem. Our leveling feet can be adjusted for further stability and firmness, eliminating wobbles or misalignments that could lead to safety gaps or operational inefficiencies.

- Hinges: Flexibility in access is crucial for maintenance and operational functionality. We build our hinges with smooth movement and durable performance, resulting in guards that are accessible yet steadfast when closed.

- Panels: Whether you want transparent panels for visibility, mesh for ventilation, or solid panels for maximum protection, we customize each to fit into your guarding system seamlessly. Every panel plays its role in safety while meeting your operational needs for visibility and access.

These custom accessories are far from being mere add-ons. They are integral components of a cohesive guarding system, each serving a specific function that enhances the overall effectiveness and usability of your safety measures.

Why Choose Faztek as Your Guarding Partner?

With Faztek, you receive more than just a safety guard; you get a comprehensive, custom-designed solution focused on functionality, durability, and simple installation. Our goal is to make your workplace safer without complicating your processes, which means your operations run more smoothly and your team stays better protected.

With over 35 years of experience in machine guarding, Faztek is not just a provider; we’re a partner in your workplace safety journey. Here’s why Faztek stands out:

- Safety-driven designs meet and exceed machine guarding OSHA standards.

- Efficient lead times signify swift implementation of guarding solutions.

- On-site support services seamlessly integrate guarding systems.

- Competitive pricing makes safety an accessible priority for all.

Invest in Safety with Faztek

Faztek’s commitment to safety is unwavering. With a range of machine guarding solutions, from perimeter guards to comprehensive enclosure systems, Faztek is equipped to handle the safety requirements of any industrial setting. Request a quote today and take the first step toward a safer workplace. Or, if you’d like to speak directly with an expert, call 260-482-7544.

Safety isn’t only about compliance; it’s about creating an environment where productivity and well-being go hand in hand. Trust Faztek to bring that vision to life in your facility.

Download our guarding solutions guide here and start your journey to a safer, more efficient workspace today.

CALL TODAY

CALL TODAY