When it comes to industrial safety, standard and custom electronic safety solutions can be the difference between a near-miss and a disaster. While out-of-the-box safety devices are a good start, customizing these solutions to the specific needs of your operation elevates the level of protection you offer your team.

This blog explores how custom electronic safety devices are not just an addition to the workplace but are fundamental to creating safer, more responsive industrial environments.

The Quest for Machine Safety: A Factory Manager’s Tale

Imagine a factory renowned for its top-notch production and automation. At its helm is Bill, a seasoned operations manager known for his sharp eye for efficiency and unwavering commitment to safety.

Bill’s day begins as always with the familiar hum of machinery and the sight of his dedicated team busy at work. Behind the usual bustle, a nagging thought has troubled him for weeks: the factory’s safety measures are good but not perfect. In this setting, safety isn’t just a priority; it’s a necessity. “Good” is simply not good enough.

Not long after, a close call near the conveyor section leaves everyone shaken. It’s a timely reminder that the current safety control systems only give basic protection. Bill needs more.

His search led him to explore various options:

- Safety light curtains can stop machinery the moment unexpected movement is detected. Are they enough on their own?

- Area scanners comprehensively monitor preset danger zones. Will they work in his factory’s dynamic environment?

- Pressure mats make emergency stops easy, but are they enough as a standalone measure?

Bill grew frustrated. Each solution, while beneficial, seems only to be a piece of the puzzle he’s trying to solve. He needs something fast, efficient, and, most importantly, custom-made to safeguard his employees and factory.

The Standard vs. Custom Safety Controllers Debate

Faztek sees a lot of people like Bill as industrial safety options continue expanding and evolving. The question arises: should you opt for standard safety solutions that broadly address common hazards, or should you invest in custom solutions tailored to the unique aspects of your workplace?

The Case for Standard Safety Modules

Standard electronic safety solutions have their place. They are tested, proven, and quick to implement. These solutions are designed to meet general safety standards and are ideal for businesses with straightforward operational processes or limited budgets. Standard solutions present a quick and cost-effective way to address the most common workplace hazards. However, the one-size-fits-all approach may only cover some nuances of every specific setting.

The Need for Custom Safety Solutions

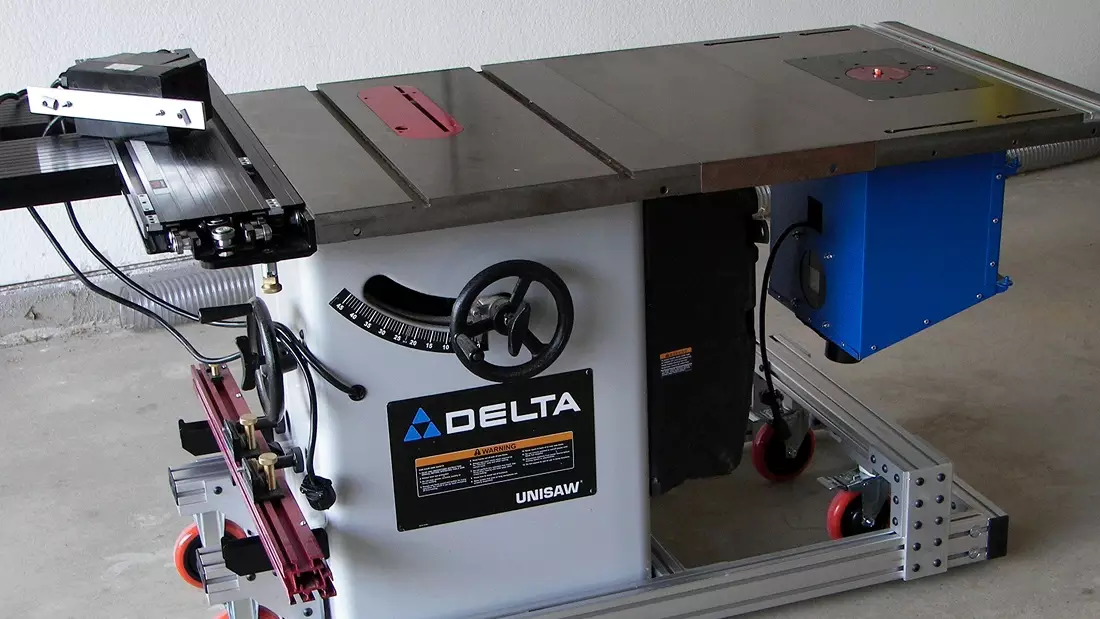

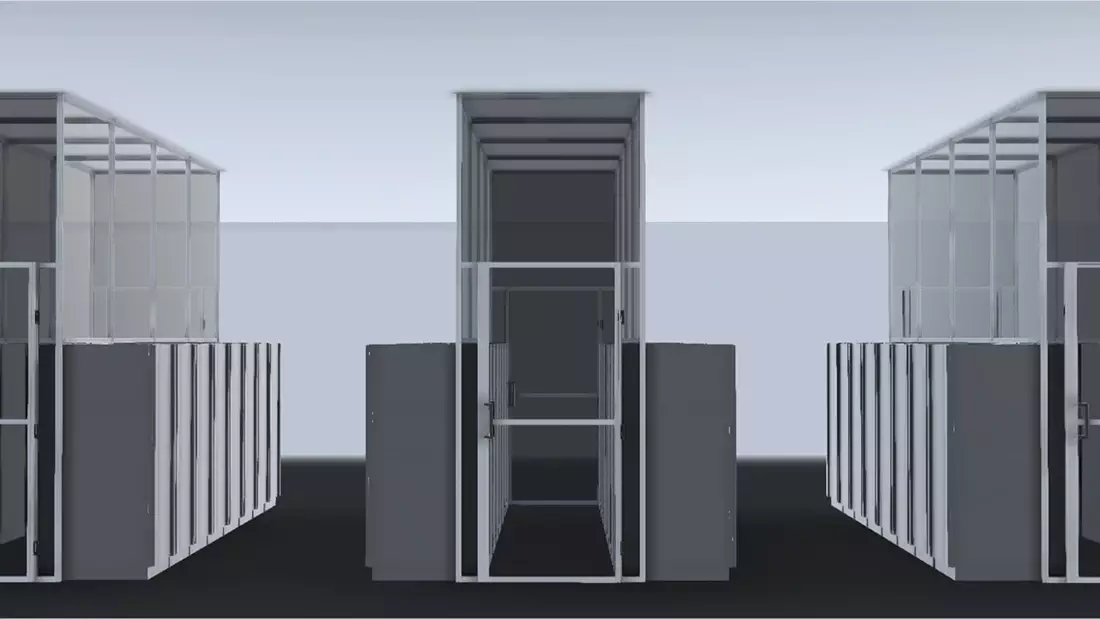

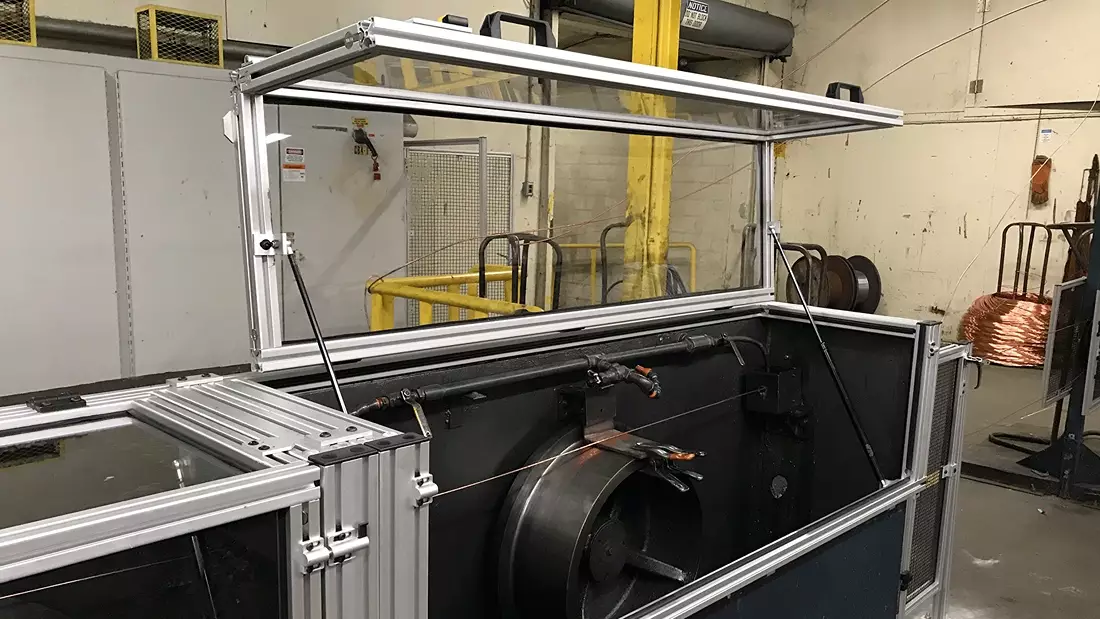

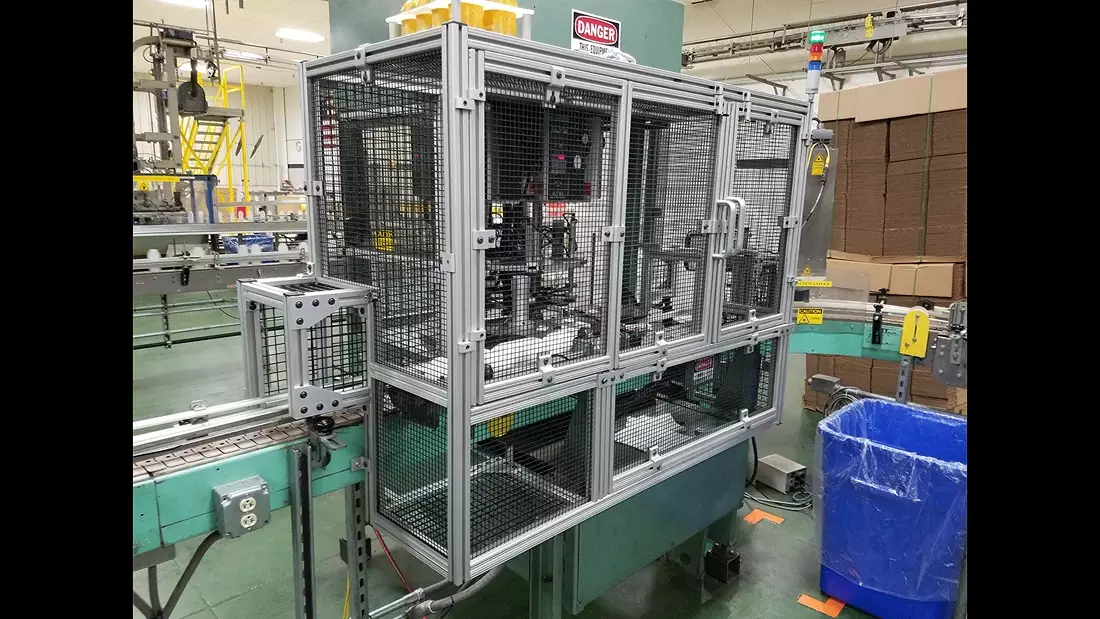

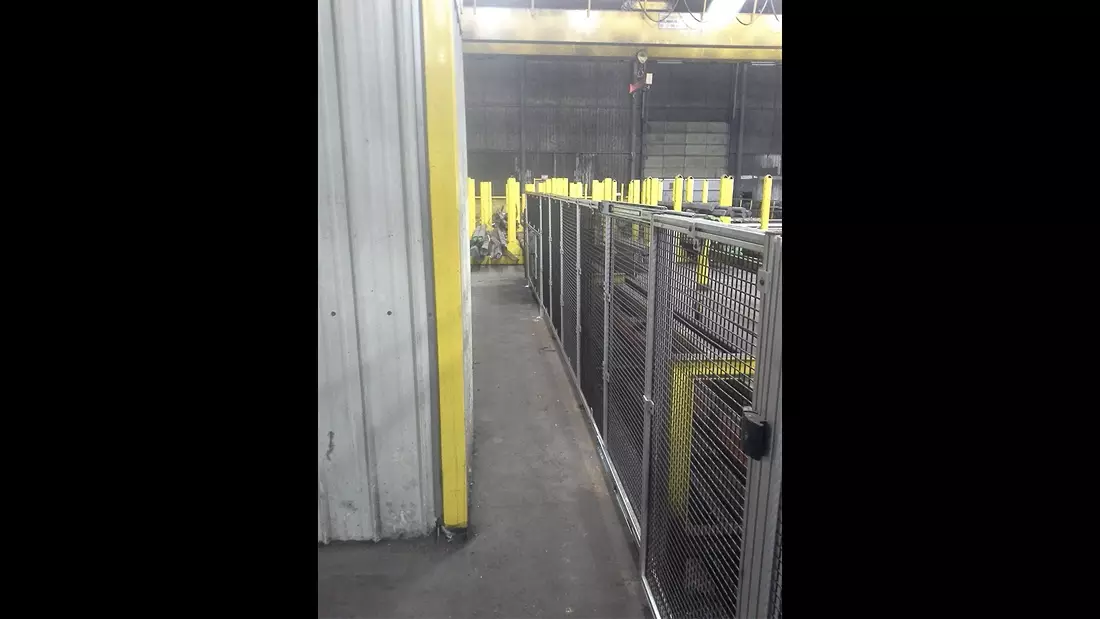

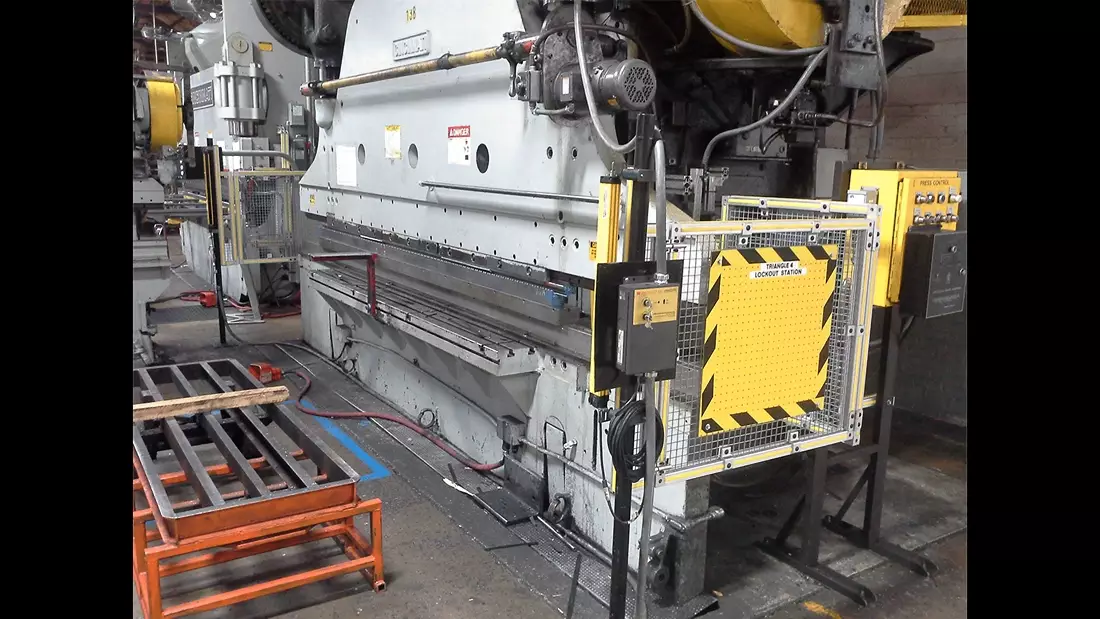

On the other hand, custom electronic safety solutions present a different value. Every workplace has challenges, from the facility’s layout to the type of machinery used and even the workforce’s skill level. Custom solutions consider your unique variables to build a safety system more precisely aligned with your workplace. Such solutions could mean designing safety guards that fit unusual machine sizes or integrating hybrid electronic safety devices for a more responsive mechanism.

Tailored safety solutions can be built from scratch or seamlessly integrated with existing systems and processes, minimizing disruption and improving operational efficiencies. Let’s not forget that different industries face varying and continually changing regulatory safety requirements. Custom safety solutions can help keep facilities compliant and safe over time.

Why Aren’t Custom Safety Solutions the Norm?

Customizing safety solutions is a complex task that demands a high level of expertise and a deep understanding of industry needs and safety standards. Many providers lack the resources or specialized knowledge to offer such tailored solutions. Generally, manufacturers focus on broader market solutions that appeal to a wider audience and are more economically viable for mass production.

Balancing Efficiency, Cost, and Safety

The decision between standard and custom solutions often comes down to balancing efficiency, cost, and the level of safety required.

Custom safety solutions have an edge over standard options for keeping your workplaces safe. These custom solutions slot in neatly with how you already work, making you less likely to have disruptions caused by safety issues. They might cost a bit more upfront, but think about the long game. By reducing accidents, you’re also cutting costs resulting from workplace injuries and the downtime that comes with them.

And here’s something to consider: it’s a big morale booster when your team sees that you’ve put in the effort to invest in safety solutions that are just right for their workspace. They feel more confident and are likely to follow safety rules more closely, and that’s a win for everyone’s safety culture.

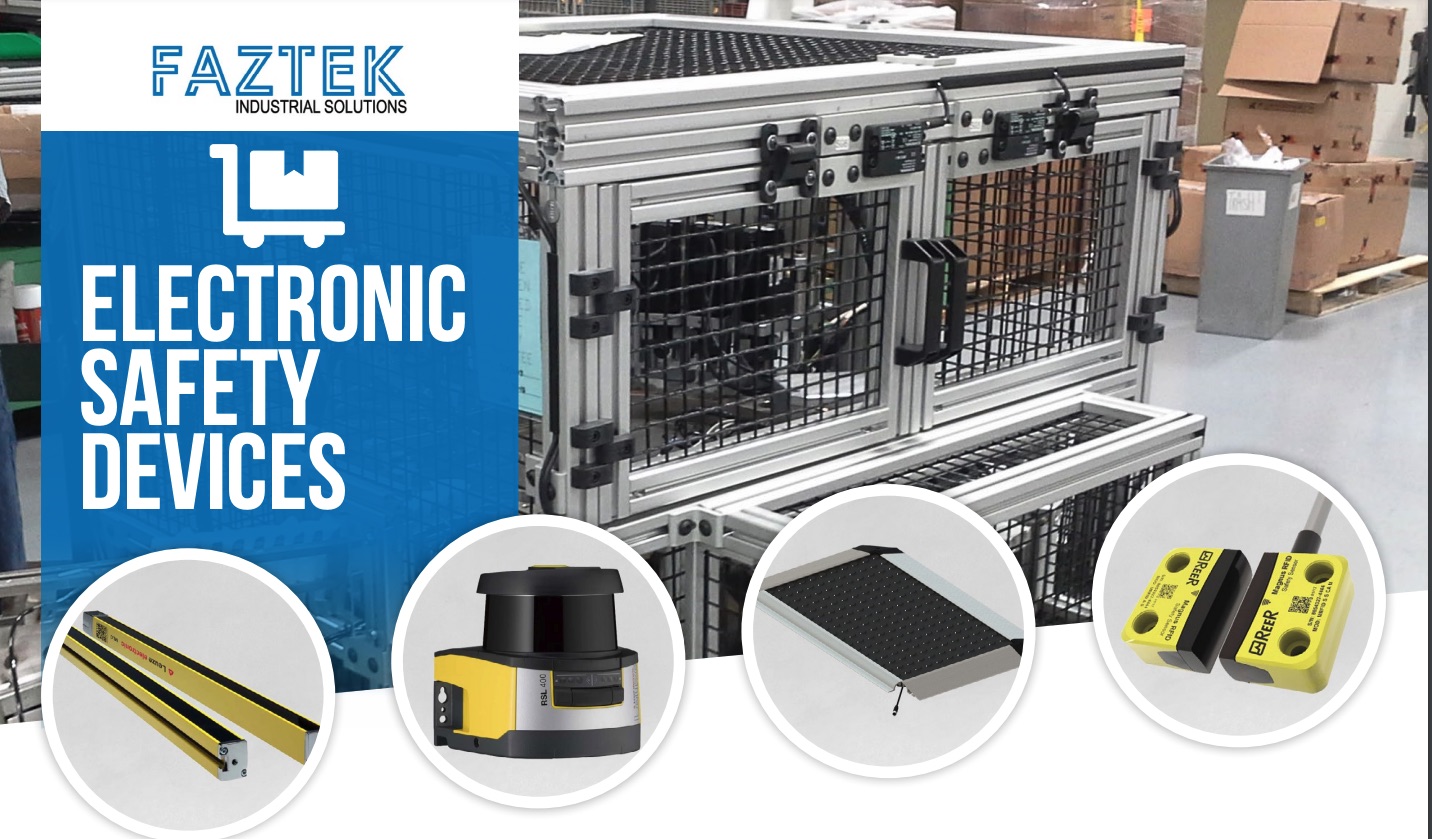

4 Electronic Safety Devices of Note

Customizing your safety approach begins with understanding the tools at your disposal. Here are four key electronic safety devices shaping the future of industrial safety:

| Device |

Purpose |

Function |

Key Benefit |

Customizability |

Safety Light Curtains

|

Create an invisible safety barrier |

Halt machine operation when light beams are interrupted |

Immediate accident prevention |

Tailor height and length to fit precise machinery dimensions |

Area Scanners

|

Monitor predefined areas for unexpected entry |

Shut down the machine when a person or object enters the danger zone |

Comprehensive monitoring of hazardous areas |

Adjust the scanning area to specific operational zones |

Pressure Mats / Safety Mats

|

Act as safety triggers for emergency stops (e-stops) |

Activate an e-stop when stepped on or when pressure is removed |

Enables immediate action in high-risk areas |

Set pressure sensitivity for foot traffic, operation conditions, and machines |

Safety Switches

|

Versatile switch options: contact, non-contact, locking, and non-locking switches |

Convert standard machine guards into active safety functions |

Easy to integrate into new or existing safety systems |

Many options are available based on operational risks and machinery types |

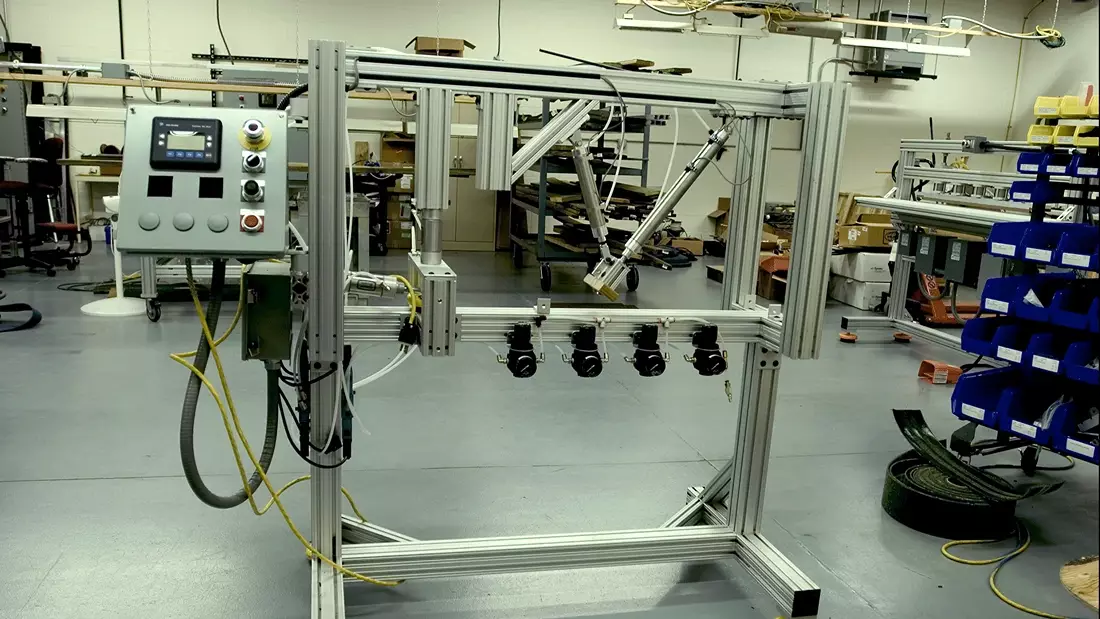

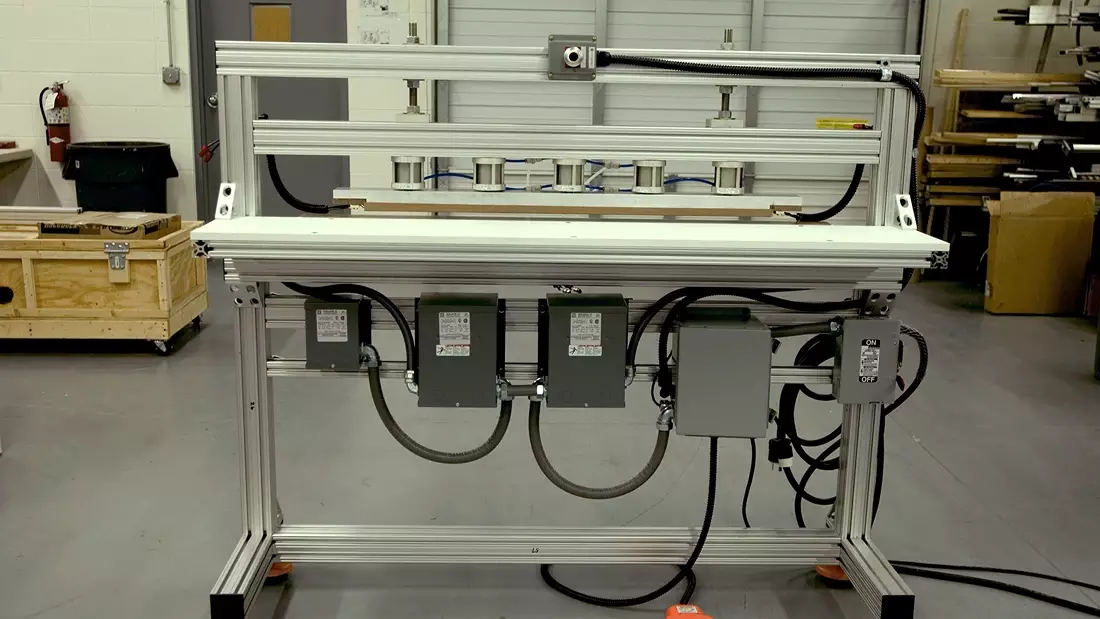

Two Is Twice as Nice as One: Hybrid Safety Solutions

While each device offers safety, the true power lies in using a combination. Hybrid safety solutions integrate two or more devices and provide a more comprehensive safety net. It’s not about layering safety measures; it’s about creating a cohesive system that accounts for multiple hazards and operational nuances.

Hybrid solutions represent a thoughtfully constructed system where each component is critical, addressing multiple hazards and adapting to the needs of your workplace. This integrated strategy ensures a broader and more robust safety net, enhancing overall protection and reducing the risk of accidents.

A hybrid system can offer immediate responses to imminent dangers and ongoing monitoring for emerging risks by combining devices like light curtains, area scanners, and safety switches. Comprehensive coverage is crucial in creating a safer work environment where employees and management can have confidence in the safety measures in place.

A Custom Approach Offers Maximum Safety

In industrial settings, where every operation is unique, a one-size-fits-all approach to safety simply doesn’t cut it. Customizing safety solutions means not just meeting the minimum safety standards but exceeding them to safeguard the work environment effectively. Investing in customized safety is an investment in your team, productivity, and peace of mind.

Remember, in the world of industrial safety, the right choice is the one that provides the most comprehensive protection for your most valuable asset: your people.

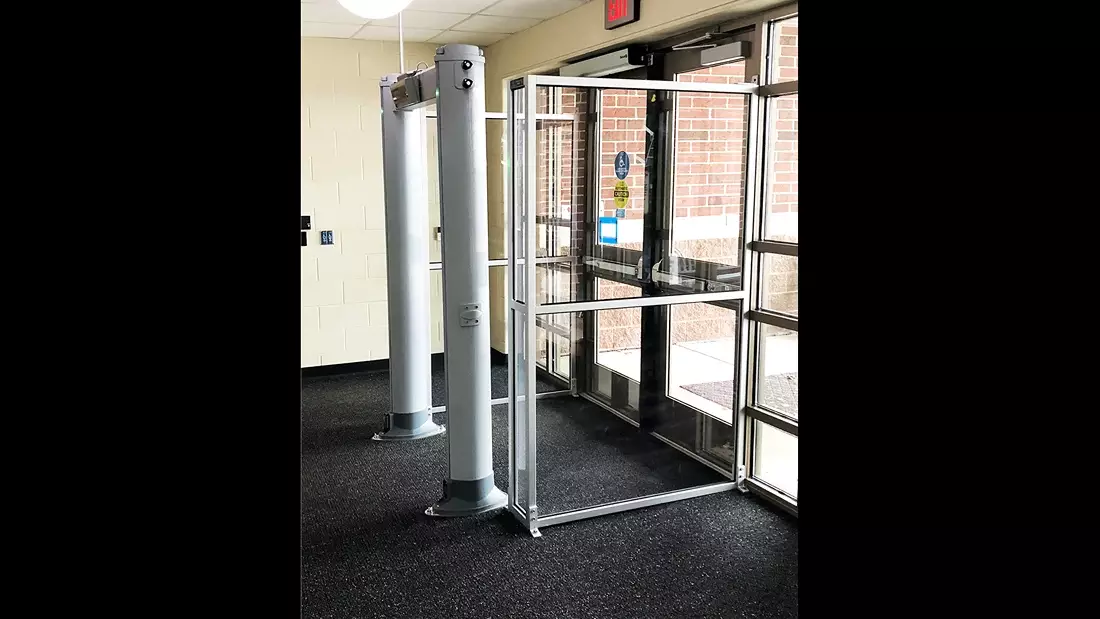

Where to Start Looking for Custom Electronic Safety Devices

Faztek’s expert team excels in crafting tailored electronic safety device solutions, including custom and hybrid systems, perfectly aligned with your needs. We are committed to working closely with you, diving deep into the intricacies of your facility to perform a risk assessment and understand the specifics of your machines.

This hands-on approach allows us to identify the most effective path to safety. With complete ownership of every stage of operation, Faztek offers unparalleled benefits to our clients. You’ll experience more robust quality control and fast turnaround times. Faztek’s streamlined process and commitment to excellence mean you get the best safety solutions customized for your workspace.

Contact us to see how Faztek can help your team.

Prefer to call? We’d love to hear from you! 260-482-7544

CALL TODAY

CALL TODAY